Credit: Shutterstock

If you have regular access to a toilet, you probably don’t give it a second thought: as you flush, a swish of water carries the waste out of sight and mind, through a network of subterranean pipes to a sewage treatment facility.

But for 2 billion people worldwide, basic sanitation services like toilets or latrines are unavailable, according to the World Health Organization. This lack of adequate sanitation contributes to the spread of diseases like cholera and dysentery, leads to the death of more than 297,000 children under age 5 every year, and translates to a global economic loss of more than $200 billion annually in health-care costs and lost productivity.

Scientists around the world are working to overturn these systemic inequalities. Many are funded through the Bill & Melinda Gates Foundation’s Reinvent the Toilet Challenge, launched in 2011 with the goal of developing low-cost, off-grid methods to treat human waste.

As part of the project, researchers have developed several self-contained toilet units that don’t require running water or extensive plumbing and that can safely and efficiently disinfect human waste. Some are fueled by solar power, while others are fueled by the waste itself. As these innovative systems shift from the lab to field testing and commercialization, researchers are striving to meet additional goals, including mitigating toilet odors and recovering valuable resources from human waste.

DECENTRALIZING WASTE TREATMENT

The Gates Foundation challenged scientists to reinvent the toilet, but as Jeffrey T. Glass points out, in reality, the toilet—merely the user interface—is only a fraction of what has to change. What happens after the flush is what scientists have to reconsider. According to Glass, codirector of the Duke University Center for Water, Sanitation, Hygiene, and Infectious Disease (WaSH-AID), the key is decentralizing and miniaturizing waste management.

“Think about taking a 10–20 acre [4–8 hectare] waste treatment area and shrinking it to the size of a port-a-potty and taking it entirely off the grid,” he says.

A typical sewage treatment plant must render human waste safe enough to discharge back into the environment. After removing solids and oils, many facilities use large vats of benign microbes to chow down on biological material that could pose a problem downstream, such as nutrients that can fuel harmful algal blooms. The remaining fluid must then be treated with ozone, chlorine, or ultraviolet light to destroy pathogens.

Unfortunately, these methods don’t translate well to miniaturized units in remote locations. Large-scale plants can more readily maintain the appropriate conditions for microbial waste treatment and are better equipped to safely store and handle large quantities of dangerous chemicals.

In the reinvented toilets, many researchers have turned to electrochemical disinfection. This low-maintenance, easily scalable approach needs no chemical additives; the only requirement is electricity. Applying a current between two electrodes submerged in black water—wastewater contaminated with human feces—produces strong oxidants that can target and kill pathogens (J. Electrochem. Soc.2014, DOI: 10.1149/2.1121410jes; Water Res. 2016, DOI: 10.1016/j.watres.2016.01.040; Environ. Sci.: Water Res. Technol. 2018, DOI: 10.1039/c8ew00698a).

“The magic happens at the anode,” says Yang Yang, a civil and environmental engineer at Clarkson University. Yang formerly worked on electrochemical disinfection as a research scientist at the California Institute of Technology with environmental scientist Michael R. Hoffmann, whose toilet design received funding in the initial round of the Reinvent the Toilet Challenge. At the anode surface, water splits to generate reactive oxygen species like hydroxyl radicals and ozone. Meanwhile, chloride ions—found in high concentration in urine—are converted to reactive chlorine species like chlorine radicals, hypochlorite, and chloramines.

In other systems, hydrogen peroxide production at the cathode can also contribute to disinfection, but it has weaker oxidation power than ozone or hydroxyl radicals, Yang says.

Researchers are continuing to fine-tune the disinfection process to optimize efficiency. For example, Glass’s team at Duke has found that instead of continuously applying a steady electric potential during disinfection, cycling pulses of electricity and circulating waste can reduce energy consumption by 68% (J. Appl. Electrochem. 2019, DOI: 10.1007/s10800-019-01292-4) and enhance hydrogen peroxide production (ACS Appl. Mater. Interfaces 2017, DOI: 10.1021/acsami.7b01614).

Minimizing the energy needed to power small-scale, on-site waste processing systems increases their feasibility for use in remote, off-grid settings. The units designed by Hoffmann’s team, for example, are entirely solar powered and can treat a batch of wastewater in less than an hour, provided the waste is properly pretreated, Yang says.

As in centralized treatment plants, pretreating waste usually entails removing solids and organic matter that can interfere with disinfection. After a flush, the Caltech-designed systems mechanically chew up waste and pump it into a small bioreactor attached to the unit, where benign microbes feast on nutrients and organic molecules. After a couple of weeks, the wastewater is ready for electrochemical disinfection (Environ. Sci.: Water Res. Technol. 2018, DOI: 10.1039/C8EW00209F). In this and other self-contained waste processing systems, the treated wastewater is nonpotable but can be recycled for flush water, hand washing, or irrigation.

WASTE—WHAT IS IT GOOD FOR?

Water is not the only valuable resource reduced, reused, and recycled in reinvented toilet systems. In the units designed by Duke’s Center for WaSH-AID, for example, the waste itself provides the fuel to operate. Postflush, corkscrew-like conveyors separate solid and liquid waste, diverting them into separate streams. The solid waste is dried and pressed into fuel pellets that power the electrochemical disinfection of the liquid waste.

Credit: Courtesy of Michael Hoffmann

Passing electric current between two electrodes submerged in wastewater (left) creates strong oxidants that can kill pathogenic microbes. In laboratory experiments, wastewater can be fully treated in 4 h (right). With proper pretreatment in field-deployed units, disinfection can occur in as little as 1 h.

Another team, based at Delft University of Technology in the Netherlands and funded by the Gates Foundation, seeks to extract energy from human waste by converting it to syngas, a mixture of hydrogen and carbon monoxide that is often produced as part of refining oil. In the researchers’ model, after waste is dried, it undergoes microwave-generated plasma gasification to form syngas. After a cleanup step to remove particulates, alkali compounds, heavy metals, acid gases, and tars, the syngas powers fuel cells that provide electricity to run the system (Energy 2014, DOI: 10.1016/j.energy.2014.03.005). Heat from the process is also recycled to help dry subsequent rounds of waste.

Researchers also hope to recover nitrogen and phosphorus from human waste for use as fertilizer. Phosphorus is particularly valuable because global supplies are running out, says Lena Trotochaud, a research scientist with Duke’s Center for WaSH-AID. And with new international standards for water quality stipulating that 80% of phosphorus and 70% of nitrogen must be removed from wastewater before release, the time is ripe to incorporate nutrient recovery into removal efforts, she says.

Trotochaud and her colleagues are developing ion-exchange materials for a module to insert into Duke’s reinvented toilet systems. These materials are high-surface-area minerals preloaded with either positively or negatively charged ions. Phosphate and ammonium ions displace these ions and remain reversibly bound to the material, making it possible to recover them for fertilizer, Trotochaud says.

The technology should be ready to test in the field by the end of the year.

EAU DE TOILET

An ancillary battle in fighting to improve sanitation across the globe is odor mitigation. The foul smells emanating from pit toilets or latrines drive many people worldwide to opt for open defecation, which leads to the spread of pathogens. As a result, the Gates Foundation has included eliminating uninviting odors and other ways to improve the user-friendliness of toilets to their goals to improve global health and sanitation.

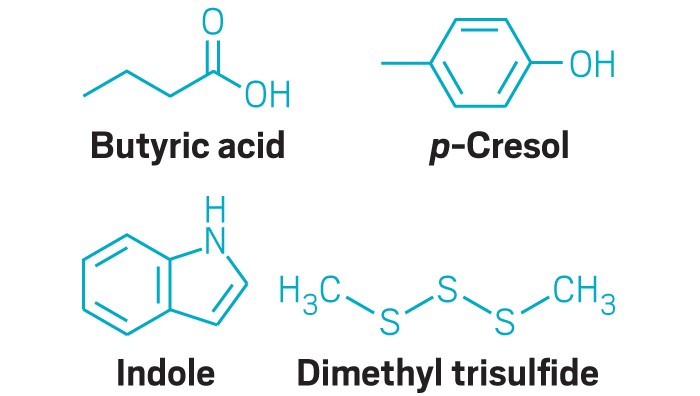

Swiss flavor and fragrance company Firmenich has partnered with the Gates Foundation to tackle troublesome toilet odors. Firmenich researchers first identified the most offensive odorants in the more than 200 molecules that make up the distinctive aroma of human feces: butyric acid, p-cresol, indole, and dimethyl trisulfide (Flavour Fragrance J. 2015, DOI: 10.1002/ffj.3293).

Think about taking a 10–20 acre waste treatment area and shrinking it to the area of a port-a-potty and taking it entirely off the grid.

Jeffrey T. Glass, codirector of the Duke University Center for WaSH-AID

Firmenich scientists also developed model latrines in which they can run controlled odor perception experiments. They inject various odorants—including mock toilet scents and perfumes—and measure how willing people are to step inside (Flavour Fragrance J. 2018, DOI: 10.1002/ffj.3450). The company scientists are also developing a fragrance that blocks the olfactory receptors responsible for detecting repulsive odors.

Modifying odor molecules through electrochemistry may also hold promise in solving the pungent problem, says Edgard Ngaboyamahina, a research scientist in Glass’s group at Duke and WaSH-AID. Pulling ambient air into an electrochemical cell could provide a simple approach that requires no additives. Most of the key malodorous molecules consist of a short carbon chain with functional groups that can be altered with electrolysis, he says.

For example, Ngaboyamahina has used electrolysis to convert the carboxylic acid group on butyric acid to an aldehyde. The resulting molecule, butanal, has a chocolaty or fruity odor. Not all the butyric acid needs to be replaced, he points out, just enough to diminish or eliminate the perception of butyric acid’s fetid, cheesy scent. Ngaboyamahina is also working on converting p-cresol to 4-hydroxybenzaldehyde, which has an almond or woody scent.

His team is still working to speed up the conversion kinetics and develop methods to target the other two odor culprits. The ultimate goal, Ngaboyamahina says, is to quickly, selectively, and efficiently eliminate the targeted molecules.

“If you convert the four odorants, you’ll still smell something,” he says, “but it won’t smell like feces.”

Credit: Courtesy of Michael Hoffmann/Eco-san

Solar-powered, containerized units made by Eco-san can process human waste collected from multiple stalls.

HURDLES AHEAD

In the end, the most important consideration in the design of these systems is the user. Will families or community members be comfortable sharing a single-toilet unit? How well do the units adhere to cultural norms of bathroom use and cleanliness?

“It’s important to keep in mind that there are people on both ends of the design process,” Duke’s Trotochaud says.

Beyond anticipating the occasional intrusion of things the toilets are not designed to handle, like a wet wipe or concentrated cleaning solutions, developers also need to consider gender equity and inclusion, Trotochaud says. For example, the WaSH-AID team has developed a compact module that it can pair with toilets to allow women to discreetly dispose of feminine hygiene products.

These four compounds have been identified as the most offensive odor molecules in human waste.

Since the Reinvent the Toilet Challenge began, much of the research supported by the Gates Foundation has moved into field testing. Duke’s Center for WaSH-AID has deployed a full-scale test unit in a dormitory for textile workers in India. The group is also in the early stages of commercializing the technology.

In 2014, Hoffmann’s group at Caltech launched Yixing Eco-Sanitary Manufacture Co. (Eco-san), a company based in Yixing, China, to manufacture its units. The company is piloting multistall units at two tourist locations and one school in China, plus a school toilet and a larger community toilet facility in South Africa, says Eco-san deputy general manager Ma Li Lin. Hoffmann’s group has also deployed prototype units in multiple locations in India.

The big next step for many toilet redesigners is bringing costs down. For example, Lin says Eco-san’s sister company, Yixing Entrustech Environmental Co., was formed to solve a critical hurdle in Caltech’s technology—the cost of the electrodes that drive the electrochemical treatment process. In just under 2 years, with “fairly intense” R&D, the company has reduced electrode costs to almost one-fifth of the original prototype’s cost, she says.

Despite this advance, Lin says the cost of the Eco-san systems remains out of reach for many governments and will require more optimization of power use and energy consumption before they’re ready for totally off-grid deployment. In fact, some of the technology may first get a foothold in developed nations. Hoffmann says he’s working with collaborators in France to install self-contained toilets in open squares and on fast trains.

Even though the reinvented toilets do not yet clear the bar set by the Gates Foundation, the progress is promising. And perhaps one of the biggest contributions thus far has been reshaping the way we think about toilets and waste treatment. Since the rise of the modern flush toilet roughly 200 years ago, very little has changed. Sewers and centralized waste treatment are often considered the gold standard, but the infrastructure is impractical and expensive to build in the many growing urban areas around the world.

Now, the area of nonsewered, reinvented toilets has become a “good field for innovation,” Lin says.

For Hoffmann, seeing these units being developed, commercialized, and out in the world has been immensely rewarding. “The last thing I thought I’d take pride in was developing a toilet system,” he says.

http://www.thisoldtoilet.com

No comments:

Post a Comment